4 Popular Types of Zirconia Crowns in Dentistry

In harmony with the swift development of science and technology, dentistry is also more and more advanced to provide various dental solutions in materials and applications for patients and dentists. The most typical example is zirconia restorations, one of the number-one priorities thanks to its outstanding advantages and various applications. This article will express the popular types of zirconia crowns, and why you should choose them for your patients.

Benefits of zirconia crowns

As one of the leading choices in fixed restorations, zirconia crowns boast a lot of benefits to affirm its position, for example:

- Long lifespan: The impressive strength of over 1500 Mpa allows zirconia restorations to bring patients long-lasting durability, from 15 to 20 years.

- High biocompatibility: The friendly ingredients in this material help ensure biocompatibility, minimize allergies for hypersensitive patients, and protect natural jawbone structure.

- Versatile applications: zirconia provides various applications such as crowns, bridges, veneers, inlays, onlays, implant bundles, and customized abutments.

- Comfortable experience: this restoration is also appreciated thanks to its lightweight and low thermal conductivity to protect patients from heaviness and tooth sensitivity.

- Various material lines: Diverse mechanical properties in zirconia block provide various product lines, for example, Ultra High Strength, High Translucent Plus Multilayer, Anterior Super Translucent, etc. to match all esthetic and quality standards.

Popular types of zirconia crowns in VTA Dental Lab

Different standards of durability, strength, and esthetics divided zirconia restorations into full solid zirconia, full zirconia multilayer, zirconia layered, and high translucent zirconia.

Full solid zirconia

Full solid zirconia is the most durable solution in this section. It has an impressive strength of up to 1500 Mpa and a long-lasting lifespan of over 20 years as well as the most cost-effective and optimal solution. However, the featured high opalescent in this material is a disadvantage for patients who prefer highly esthetic restorations. Therefore, full solid zirconia is prescribed for posteriors, which bear strong mastication force, rather than interiors.

Full zirconia multilayer

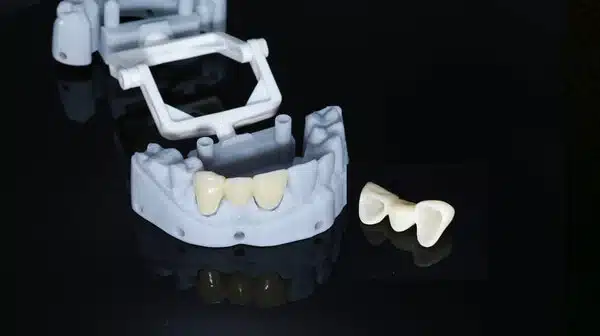

The second type is full zirconia multilayer, which is an advance in dentistry. This material is composed of many different dentine, gradient, and enamel layers, each layer corresponding to a separate strength and translucency level, which are arranged each on top of the other (some discs have up to 16 layers) so that makes a natural color transition from darker to lighter, from opaque to translucent in gingival to incisal.

Zirconia Multilayer products are appreciated thanks to their ability to match the standard colors, natural-looking, and various CAD/CAM technology, from now on, optimize production time effectively.

Zirconia layered

Zirconia layered is the most aesthetical restoration for anterior crowns. Thanks to the combination of professional porcelain hand-building and stain skill, this product offers impressive aesthetics with natural translucence and color gradation while maintaining exceptionally high compatibility.

High translucent zirconia

A thin porcelain layer is built up on a full solid zirconia crown by technicians to help the finished products boast impressive strength and light translucence.

This comprehensive solution is suitable for anterior to posterior crowns, especially for those who like both natural-looking and durable crowns.

Digital zirconia crowns

In addition to the great benefits of aesthetics, durability, and biocompatibility as well as the variety of treatment methods mentioned above, zirconia crowns are also highly appreciated thanks to the inclusive advantage in the digital dentistry field.

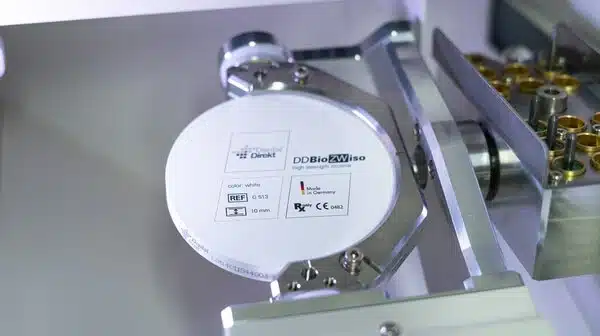

Zirconia discs have numerous shapes and sizes and easily integrate with almost any milling machine in the market.

Moreover, the digital zirconia production process will be almost totally automated by cutting-edge equipment systems, from now on, helping to ensure the accuracy of the finished product and optimize production time. These factors contribute to helping patients have a better customer experience, thereby enhancing your office’s position and profits.

How to manufacture a digital zirconia crown in the VTA dental lab

VTA Dental Lab is at the forefront of digital dentistry in general and digital zirconia in particular. The most concrete proofs are:

- No limit scanning technology

- 3D Design Center with over 100 professional technicians and experts

- 3D Printer Center with more than 40 machines

- CAD/CAM Center with over 50 machines

A digital zirconia manufacturing process in VTA consists of:

-

Sending digital file

In the first step, dentists will make impressions for customers with digital scanners and send scanning files to us via digital@vtadentallab.com.

VTA Lab accepts diverse scanning technologies such as 3shape, Itero, Medit, Cerec, etc.

-

3D Design

Our technicians will design digital models and restorations in 3shape and Exocad software.

-

Model printing

The 3D Printing Center will print digital models according to design files.

-

Milling and sintering

CAM Center will mill the restorations with state-of-the-art equipment of over 50 Imes-score, Roland, and Aidite milling and sinter with Germany sintering technologies to maximize productivity.

-

Crown finishing

After that, digital cases will be contoured and stained to achieve aesthetic standards.

-

Final QC

The most experienced experts in our lab will check the accuracy of outgoing cases such as the bite, color, margin, and so on.

-

Packing and delivering

The finished cases will be verified and wrapped carefully to be delivered by reliable international airlines such as UPS, DHL, and FedEx.

In conclusion, with many prominent features in quality, esthetic, applicability, and safety, zirconia crowns deserve to be one of the number-one priorities for dental patients. With our capacity and dedication, VTA strongly believes that we can offer excellent restorations in both digital and physical methods at the best price, quality, and turnaround time.