Explore The Amazing Benefits Of CAD/CAM Dentistry

CAD/CAM dentistry is an advanced digital dentistry method that is increasingly popular and developing in the 4.0 era. The use of technology and digital solutions is essential to achieve optimal results and reduce costs in all areas of life in general and in the dental field in particular.

What Is CAD/CAM Dentistry?

CAD/CAM Dentistry (Computer-Aided-Design and Computer-Aided-Manufacturing) is an integrated system combining design and manufacture with computer support to create precise and efficient dental restorations including crowns, bridges, veneers, inlays and onlays, implant-supported restorations, and orthodontic appliances. CAD/CAM process can help dental professionals create restorations faster, more efficiently, and sometimes more accurately than traditional methods. It can also improve the patient experience by reducing the time patients spend in the chair and eliminating unpleasant processes like taking impression molds. (Source link )

CAD/CAM Dentistry Equipment

The Operational Process Of CAD/CAM Dentistry

The CAD/CAM Dentistry follows a precise procedure that includes several steps from initial data collection to production and assembly of restorations, with the specific process as follows:

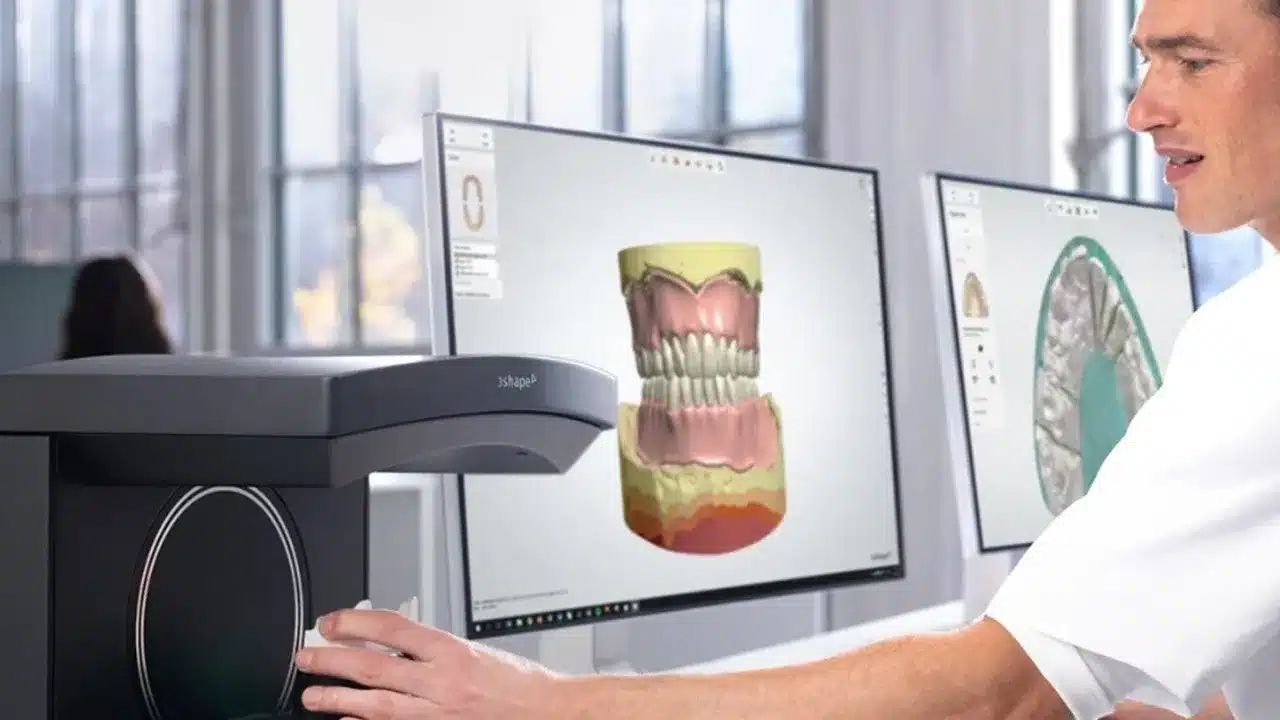

1. Digital Dental Impression: after a thorough examination and oral hygiene, the dentist will use a thin handheld intraoral 3D scanner, placing it in the patient’s mouth to capture images in just a few seconds. These scanners are equipped with a camera system and LED lights, allowing for quick imaging and video recording of the shape and contours of the patient’s teeth, providing a highly accurate and detailed representation of the oral anatomy. This scanning step eliminates the need for traditional dental impressions, providing maximum comfort for the patient and allowing the dentist to obtain a 360-degree view of the impression.

Digital Dental Impression In CAD/CAM Dentistry

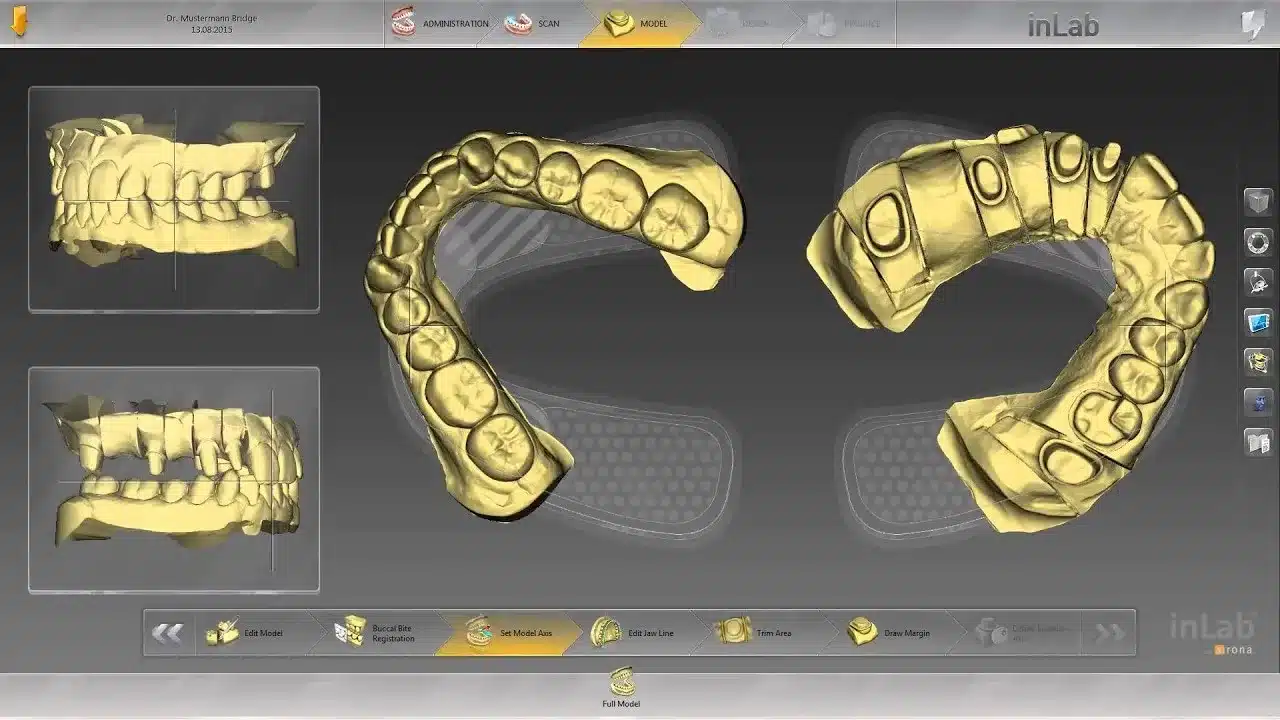

2. Design: 3D images from the digital scanning process are imported into CAD software. The dentist or dental technician uses this software to design the restoration, adjusting the size, shape, and color to match the patient’s natural teeth best. Additionally, the software includes tools for contact analysis, bite checking, and assistance in selecting suitable materials.

Design in CAD/CAM Dentistry

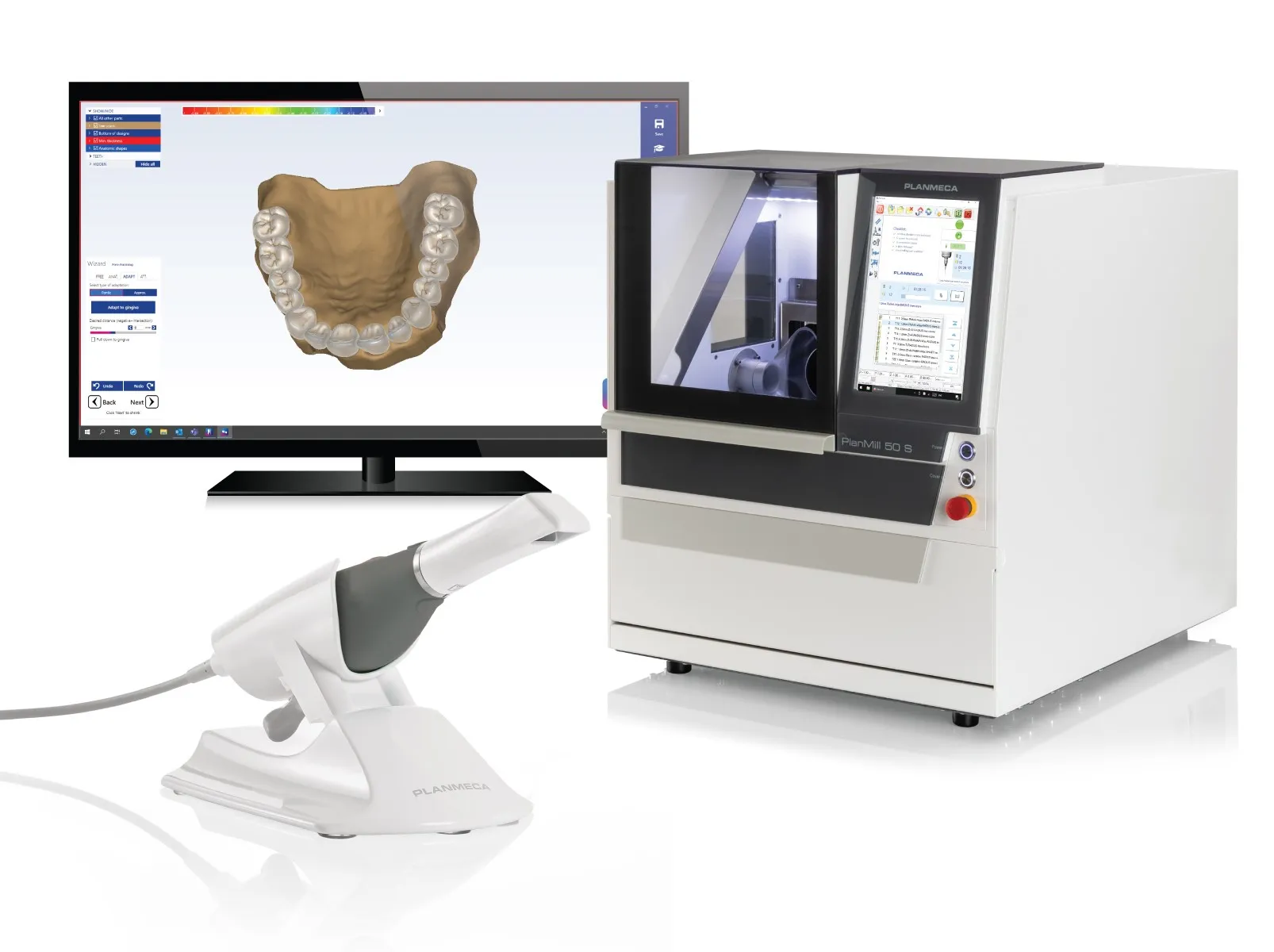

3. Manufacturing: once the design is complete, the design data is sent to the CAM machine to manufacture the restoration from materials such as ceramic, zirconia, titanium, gold, composite resin, etc. This process can take place either in the clinic or at a dental lab.

Milling Machines

4. Bonding and Adjustment: the final step in the process is for the dentist to receive the restoration and permanently attach it to the patient’s tooth, checking the bite and chewing function to ensure maximum comfort for the patient. The dentist also guides how to care for the new restoration to ensure its durability and proper maintenance.

Bonding and Adjustment-CAD/CAM Dentistry

Advantages Of Cad/Cam Dentistry Compared To Traditional Dentistry

Time and Cost Saving The biggest advantage of CAD/CAM dentistry is speed. These techniques can deliver dental products in just one day, and sometimes in a few hours if the dentist designs and manufactures in-house, this results in cost savings for dental clinics and laboratories. In addition, CAD/CAM dentistry typically also requires fewer patient visits, one for the intraoral scan and one for the placement, making it more convenient and reducing patient wait times.

Accuracy and Superior Aesthetics The quality of products created using CAD/CAM dentistry is higher in accuracy, minimizing errors compared to traditional dental methods. CAD/CAM Dentistry can also be highly customized to match the patient’s natural teeth closely. CAD software enables technicians to precisely manipulate shapes, sizes, and shades to create restorations that blend seamlessly with the patient’s smile.

Enhanced Patient Experience Besides reducing appointment and wait times for patients, CAD/CAM Dentistry also eliminates the use of traditional impression materials that can be uncomfortable, especially for sensitive patients or those with strong gag reflexes to viscous alginate materials, enhancing the overall patient experience.

Cad/Cam Dentistry Compared To Traditional Dentistry

Disadvantages Of Cad/Cam Dentistry

Like any new technology in dentistry, CAD/CAM dentistry also has some drawbacks. Firstly, the cost can be the biggest barrier for dental clinics and laboratories. The initial investment in CAD software, 3D printers, milling machines, etc., can be substantial. Additionally, to operate the new software and equipment effectively, staff need time to become familiar with and learn how to use them, which can be a challenge for technicians accustomed to traditional dental methods.

The Development And Prospects Of Cad/Cam Dentistry In The Future

The introduction of CAD/CAM dentistry has changed how dental practices and dental labs handle impressions, design, and manufacturing. Advancements in digital scanning technology, advanced CAD software, modern CAM machines, and the development of new materials are driving the growth of CAD/CAM dentistry, transforming a previously manual process into a digital one that optimizes costs and time while enhancing patient satisfaction.

The integration of AI and machine learning, the development of tele-dentistry services, and the widespread application of aesthetic dentistry promise to create opportunities for CAD/CAM dentistry to become more widely adopted.

The Development And Prospects Of Cad/Cam Dentistry

VTA is one of the digital dental laboratories that seamlessly integrates with existing dental software and equipment, ensuring precise and smooth workflows between dental clinics and dental laboratories. VTA’s CAD/CAM software system allows for the integration of digital imaging software and existing patient records from the dental clinic, as well as enhancing the quality performance of digital processes with the production and fabrication of restorations. Start collaborating with VTA today to elevate your practice. Visit our website for more information https://vtadentallab.com/ or contact us via email: info@vtadentallab.com