The Future of Removable Prosthetics: 3D-Printed Chrome Denture Frameworks

In today’s fast-moving world of dental innovation, 3D-printed chrome frameworks are setting a new benchmark for removable prosthetics. At VTA Dental Lab, we’re proud to bring this advanced solution to our partners—combining digital precision with the proven strength of chrome cobalt for outstanding clinical performance and patient satisfaction.

What Are 3D-Printed Chrome Denture Frameworks?

Traditionally, cobalt-chrome (Co-Cr) partial denture frameworks were made using wax-ups and lost-wax casting. Although reliable, these techniques often involve multiple manual steps, increasing the risk of distortion and inconsistency.

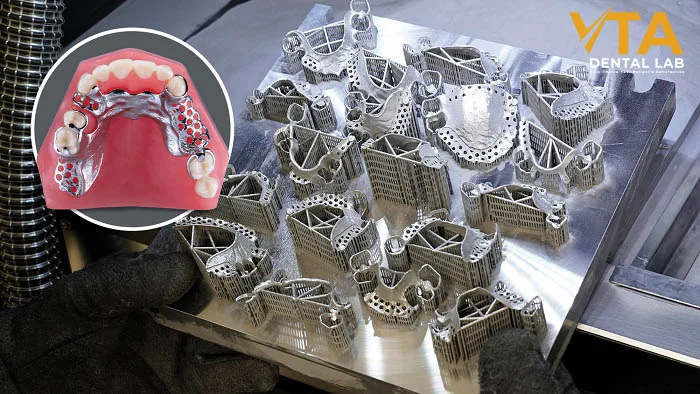

3D printing transforms this process through Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). These additive manufacturing methods use precision lasers to fuse fine metal powder layer by layer, creating a digitally designed framework with exceptional fit and accuracy.

Key Benefits of 3D-Printed Chrome Frameworks

Superior Accuracy and Fit

Digitally designed frameworks ensure precise adaptation, minimal chairside adjustments, and enhanced patient comfort.

Design Flexibility

CAD technology allows for greater control over clasp positioning, thickness, and support structures—ideal for complex or aesthetic cases.

Consistent Quality

Unlike casting, which depends on manual craftsmanship, 3D printing guarantees repeatable, high-quality outcomes every time.

Faster Turnaround Time

The digital workflow shortens production cycles. STL files can be uploaded instantly, frameworks printed overnight, and delivered faster to your clinic.

Lightweight but Durable

SLM-produced chrome cobalt frameworks offer excellent strength-to-weight ratios—durable, comfortable, and long-lasting.

Our Workflow at VTA Dental Lab

Step 1: Digital or Physical Impressions

We accept both conventional impressions and intraoral scan files (STL).

Step 2: CAD Design

Our technicians design the framework digitally for optimal fit and retention.

Step 3: 3D Metal Printing

Using high-powered lasers, the Co-Cr framework is built with micron-level precision.

Step 4: Post-Processing & Finishing

Polishing, smoothing, and refinement ensure both functional accuracy and aesthetics.

Step 5: Delivery to Clinic

The final framework is returned ready for try-in or prosthetic setup.

Perfect For a Range of Cases

- Complex partial denture cases

- Patients with high aesthetic expectations

- Fast-turnaround restorations

- Replacements for broken or ill-fitting cast frameworks

Why Choose VTA Dental Lab?

At VTA Dental Lab, we integrate craftsmanship with advanced digital manufacturing. Every 3D-printed chrome denture framework we produce is engineered for precision, strength, and comfort—helping you deliver superior prosthetic outcomes with fewer remakes and happier patients.

Upgrade your removable prosthetic workflow today.